Proven, Rated, Tested: Maxxon Acoustic Isolation System.

Here’s Why Maxxon Remains the Leader in Fire Safety and Sound Control for Multifamily Construction.

Science Behind Fire Safety

For over 50 years, Maxxon® Gyp-Crete® underlayment has been used in multifamily construction as an effective fire-safety solution. The gypsum component of Maxxon Gyp-Crete products is an effective heat sink. Chemically combined water is released from the Gyp-Crete between 200-300°F, absorbing heat from a fire and slowing its spread. In addition, Maxxon Gyp-Crete provides a strong, flat, level surface that can compensate for framing issues and is ready for most floor coverings. Gyp-Crete can be used to smooth transitions where different flooring products intersect, such as between a kitchen and a living space. The mass of a Gyp-Crete pour is also an important component of a complete, high-performing, sound control system.

New Demands in Multifamily Design

Over the last few decades, reducing noise transfer in multifamily construction has become an important consideration. Driven by code and occupant demands, sound attenuation is now a significant factor in multifamily design and construction. Sound transfers through buildings as impact and airborne sound. Examples of impact sound transmissions include footfalls, dropped objects, and moving furniture. In the building industry, impact sound is rated as IIC (Impact Insulation Class). Airborne sound transmission typically occurs from voices, music, and televisions. Airborne sound is rated as STC (Sound Transmission Class).

Science Behind Sound Control

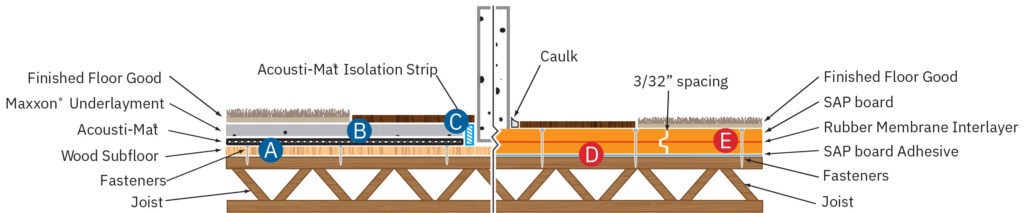

As a leader in sound attenuation for buildings and fire-resistant underlayments, Maxxon offers proven, rated, and tested flooring systems to achieve code requirements for both fire-safety and sound control, while also meeting the desired levels of acoustical comfort. The Maxxon Acoustic Isolation System includes a Maxxon Gypsum Underlayment to create a solid mass that blocks airborne sound transmission; a Maxxon® Acousti-Mat® to provide an air gap that helps dissipate impact sound; and Maxxon® Acousti-Mat Perimeter Isolation Strips to optimize noise reduction and protect against sound transmission. By design, the Maxxon Acoustic Isolation System does not use mechanical fasteners. This eliminates the potential for flanking paths which aid in sound transfer. Backed by more than 200 published sound tests and over 140 UL and ULC fire-resistance rated designs, the proven assemblies of the Maxxon Acoustic Isolation System deliver performance and peace of mind for designers, developers, builders, and occupants of multifamily buildings.

Education: Protection From Falling Overboard

Recently, oriented-strand wood, cellulose fiber, and magnesium oxide (MgO) board products have been marketed as an alternate underlayment solution for multifamily properties. As the leader in fire-safety and sound control for multifamily construction, Maxxon wants to address confusion surrounding these products. Since Maxxon is committed to advancing the industry, not only through innovation, but education as well, we encourage you to evaluate the options carefully.

Before putting your project at risk, take a closer look at what’s beneath the board claims by asking these questions.

What is the product’s fire rating, and how many UL and ULC fire-resistance rated designs are available?

Maxxon products are Class A Fire Rated and available in more than 140 UL and ULC fire-resistance rated designs.

How many sound tests are available for the product?

Maxxon products are backed by more than 200 published sound tests. In addition, Maxxon’s headquarters is home to the world’s largest floor-ceiling sound chamber where our scientists have the resources and flexibility to conduct a range of sound tests in a controlled, NVLAP accredited (lab 600320-0) environment. With on-site testing capabilities, Maxxon has the ability to perform testing on our own products and the flexibility to pursue basic acoustics research.

Does the product require metal fasteners such as nails or screws for installation?

These mechanical methods, along with adhesives, can create pathways that allow the transmission of impact and airborne sound. The Maxxon Acoustic Isolation System eliminates any use of metal fasteners or sound transferring adhesives.

Does the installation require expansion gaps or other spaces between product and walls? Are gaps required between product and plumbing and electrical protrusions?

Gaps and spaces created in board product installation provide open channels for sound transmission. The Maxxon Acoustic Isolation System provides a fully isolated floating floor system, eliminating the gaps or spaces that permit unwanted sound transfer.

How do fasteners and gaps impact the finished flooring contractor?

Any gaps between boards, or dimples created by fasteners, will need to be filled and feathered by the flooring contractor. This adds extra, unaccounted for time to the project. Once installed, the Maxxon Acoustic Isolation System needs no additional prep. It is ready to accept virtually all finished floor goods.

Is the speed of installation quantified; how many square feet can be covered in a day?

Maxxon Gypsum Underlayment installs at a rate of 20,000-30,000 square feet per day. Other trades can resume their work the next day.

How does the product accommodate variances in the subfloor it is covering?

Framing variances happen, but before a finished floor can be installed, these variances must be addressed according to the flooring manufacturer’s flatness recommendation. Placing a board product atop an out-of-level subfloor will not resolve the issue. During installation, the Maxxon Gypsum Underlayment can correct any out-of-level subfloors and compensate for framing inaccuracies, and it easily addresses transition areas between different finished flooring products.

What environmental conditions are required for installation?

One product’s installation requirements state: “the temperature and humidity conditions of the building must closely approximate those conditions which will exist when the building is occupied.” As construction professionals know, the environmental conditions experienced during the construction phase rarely match the conditions of occupancy. The Maxxon Acoustic Isolation System can be installed at temperatures ranging from 50°F to 100°F in nearly all humidity conditions.

What happens when flooring renovations are needed?

Glue-down flooring products, adhered directly to board panels, can damage boards during removal and require board replacement during flooring renovations. The Maxxon Acoustic Isolation System allows for flooring replacement without compromising the sound control system.

Is consistent and quality installation assured?

Improperly installed board products increase the likelihood of compromising sound control. Maxxon Gypsum Underlayment is installed by trained and licensed applicators, who provide the necessary attention to detail required for a top-performing sound control system.

Can the manufacturer meet your quantity demand and delivery window?

Maxxon produces and ships products from four USA-based manufacturing plants to effectively address the order quantities and construction schedules of customers across North America. Supply chain issues are a non-issue with Maxxon.

Side-by-Side, Maxxon Outperforms Across the Board

When carefully reviewing critical details, it’s clear that Maxxon outperforms board products. Both during the construction process and throughout occupancy and renovations, the Maxxon Acoustic Isolation System remains the superior fire-safety and sound control solution for multifamily construction.

Building professionals seeking proven solutions can access Maxxon’s Fire & Sound Manual — which features an extensive list of sound-tested and UL listed assemblies organized by construction type — and Maxxon’s Interactive System Selector to identify which assembly featuring Maxxon’s Acoustic Isolation System is the best fit for ensuring a code-compliant and quieter environment for their building’s occupants. Access the links below to get started, or contact your Maxxon rep.